Towards Energy Efficiency Improvements using AI-Driven Generative Design

Generative design (GD) is an innovative paradigm in engineering that employs advanced algorithms and computer-aided tools to create optimized designs. Specifically, generative design in construction aims to refine building and infrastructure designs. Generative design approaches systematically explore numerous design options by inputting desired objectives, such as structural performance, materials, costs, and comfort preferences. It subsequently generates a variety of potential solutions that meet or exceed specified criteria, assisting architects and engineers in identifying the most efficient, sustainable, and innovative designs. This approach enhances creativity, reduces design time, and can lead to more resource-efficient construction projects.

GD has harnessed the potential of artificial intelligence (AI) to assist architects, constructors, and building developers in analyzing alternative designs based on high-level specifications and requirements (design constraints and performance objectives). Among the various AI techniques applicable to enhancing building design, three are the most commonly utilized:

- Knowledge representation allows rule-based and ontology-driven software to support the processes of regulatory compliance, design constraint checking, and access to design information.

- New approaches based on generative AI (GAI) have demonstrated significant potential in other creative domains; however, they still lack consistency and limit the designer’s agency in critical areas with technical constraints, such as architecture.

- Simulation-based optimization has been effectively applied in numerous engineering and design scenarios, employing an optimization layer atop several mechanistic simulations.

Simulation-Based Optimization: A Designer-Centric Approach

The last of these approaches merges the designer’s agency with the constraints of a rigorous simulation-driven design process, wherein all generated solutions are accurate and valid from a thermo-structural perspective. This simulation-based optimization method is guided by a core optimization process that explores candidate solutions through a stochastic exploratory search, where alternative designs are generated iteratively. In each iteration, the solutions are evaluated and ranked based on their simulation results, and from those deemed more promising, new candidate solutions are proposed by combining and modifying the best-performing solutions. The process of combining and modifying new candidates is dictated by the optimization techniques used for this problem. Specifically, these techniques should support two search processes: exploration and exploitation. Exploration allows the optimization strategy to search in areas of the solution space that have not been previously analyzed, while exploitation intensifies the search within a limited area, concentrating on fewer variations of the solutions to refine a good solution. An appropriate optimization strategy should encompass both, leaning towards one or the other based on the quality of the results and the stage in the optimization process, primarily exploring first and exploiting later.

Soft Computing Techniques in SNUG’s Optimization Component

In SNUG, the optimization component of this GD approach is implemented using two distinct soft computing techniques. Unlike traditional hard computing methods, soft computing is a branch of computer science focused on computational techniques capable of tolerating imprecision, uncertainty, and approximation. It encompasses various methodologies, including fuzzy logic, genetic algorithms, neural networks, and probabilistic reasoning, which are employed to address complex real-world problems that are difficult to model precisely. Specifically, SNUG employs, on one hand, a hybrid self-adaptive heuristic optimization technique called Multiple Offspring Sampling (MOS), which combines differential evolution and local search mechanisms, and on the other hand, neural network models that serve as surrogates for the simulation to filter out non-promising candidate solutions.

The second component of a simulation-driven optimization approach to GD is the simulation component. In this instance, simulations serve as the mechanism to evaluate the quality of the candidate solutions. Thus, an improvement in selected indicators derived from the simulations would indicate that one solution is superior to another, providing the criteria for the optimization strategy to guide the assisted design process. The effectiveness of the combination of simulation and optimization relies on the accuracy of the simulations. Consequently, the ultimate quality of the design proposed by a GD approach is constrained by the precision of the simulation and the efficiency of the optimization process in discovering viable designs within the extensive space of potential solutions.

SNUG’s Practical Implementation: Integrating Simulation Models

SNUG provides a practical example of this approach by employing various simulation models to optimize outcomes. For instance, Energy+ simulates energy consumption alongside comfort—considering ranges of preferred temperature and humidity conditions—and employs other models to estimate life cycle assessment (LCA) and construction costs. All these simulations and other metrics implemented in a programmatic assessment of the candidate solutions require a curated database of materials. In particular, for those new materials also proposed as part of SNUG. These materials include all the parameters necessary for their simulation, requiring a good characterization of the thermo-mechanical properties and the additional LCA-derived information.

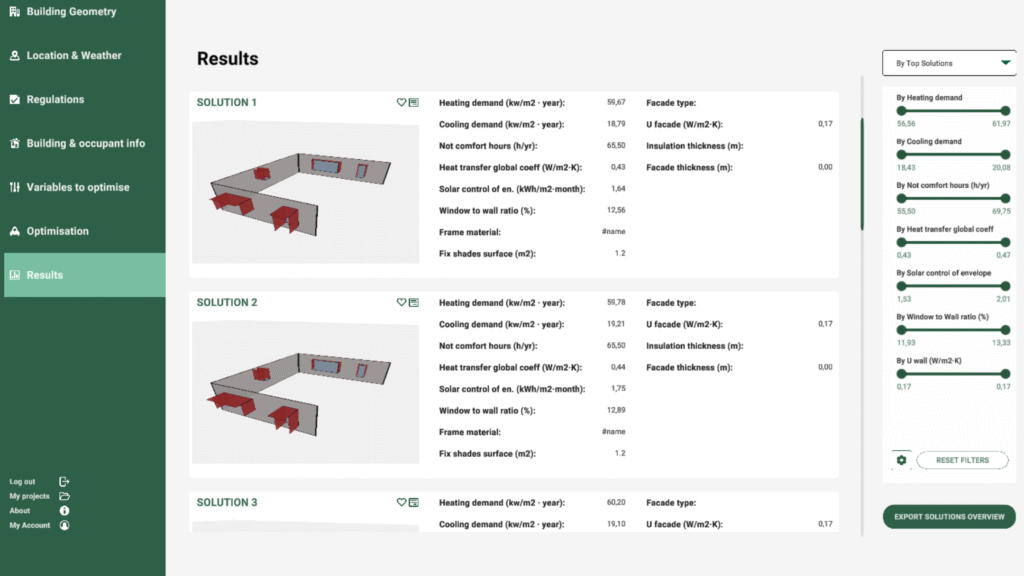

SNUG’s Digital Assistant Tool (DAT): A Comprehensive Solution

Together, these techniques (simulation and optimization) establish the foundation of SNUG’s Digital Assistant Tool (DAT). This tool facilitates the refinement of the building’s envelope design. DAT utilizes an extensible catalogue of sustainable materials to define the layers of the constructive elements that comprise the façades and roof. This catalogue includes two key components: first, a database of properly characterized materials (both standard and new), specifically tailored for the parameters required by the simulations.The second part consists of templates outlining how construction systems are designed, detailing the number of layers, the types of materials, and which are mandatory or optional. DAT employs these templates to generate alternative construction systems and test them as part of the building design; consequently, they serve as the generative elements defining feasible and valid construction systems for the building’s envelope.

The typical use of the SNUG DTA is intended to be an integral part of the existing design workflow. The architect models the building in BIM, and this BIM model is provided as input to the DTA. The tool allows for the configuration of which elements of the envelope we wish to refine (which façades or roof sections), the criteria to optimize or use as design constraints (e.g., minimizing energy consumption with a maximum of 100 hours of discomfort per year), and the selection of elements in the catalogue (materials and templates) that she wishes to use. The tool then iterates through the various potential configurations and presents several new alternatives for those elements; for the selected one, it replaces the systems and materials in the BIM model.

Download full article in pdf here.