SNUG 2nd General Assembly: Shaping the Future of Zero-Energy Buildings

The SNUG consortium gathered on November 13-14 in Stuttgart for its second General Assembly, hosted by the University of Stuttgart. Over the course of these two days, 17 partner entities from 11 countries came together to advance SNUG’s mission: reshape the construction industry and drive the transition to Zero-Energy Buildings (ZEBs). This meeting marked a significant milestone as we have completed the first year of the project.

Key discussions

Since we are one year into the project, there was much to plan and discuss. We reflected on the progress accomplished, refined objectives, and charted the steps ahead. The agenda covered each work package in detail, with partners sharing their results, addressing challenges, and outlining upcoming tasks.

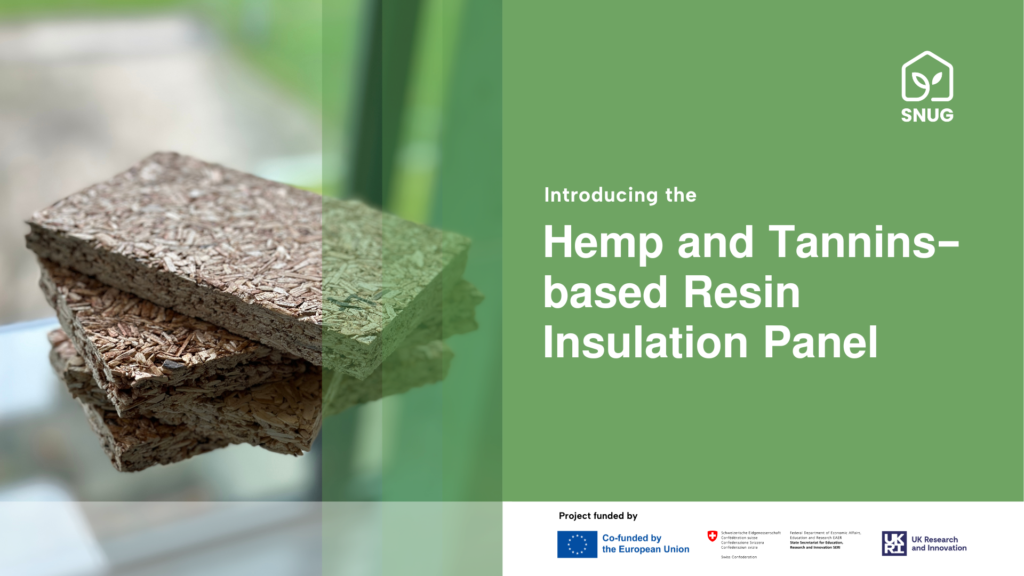

Day one highlighted significant achievements in the pilot scale development and testing of our innovative thermal insulation solutions, including:

– aerated eco-concrete blocks;

– self-leveling mortars with PCMs;

– aerogels;

– biobased panels.

Additionally, our Digital Tool Assistant is also taking shape, with advancements in software requirements, data collection, and UI design. The day concluded with an overview of the roadmap for the three project demonstrators in Switzerland, Spain, and Norway.

Day two shifted the focus to project management and strategies for amplifying SNUG’s impact. Partners explored ways to effectively communicate and disseminate the project’s outcomes to stakeholders, while also devising plans to exploit future results and foster market adoption.

As we transition into the second year of the project, the focus will be on Life Cycle Assessment (LCA), techno-economic evaluations, industrial trials to scale production, and the launch of our demos in real-life buildings across Europe.

Labs tour

To complement the discussions, our hosts at the University of Stuttgart – Institute of Construction Materials organised a tour to their labs, where the consortium partners had the chance to get a firsthand look at mockup walls where SNUG’s innovative solutions are being tested and learned about the different tests conducted.

First mockup wall: Insulation was tested by blowing it in

Second mockup wall: Insulation was subjected to external stimulus through a climatic chamber

Participants toured various labs: concrete and mortar labs (mechanical testing, mortar development, wet rooms for curing, and thermal conductivity evaluations), chemistry labs (academic and industry purposes), fire testing labs (fire resistance testing for construction materials and toxicity assessments of fumes/smoke), and timber labs (construction-grade woodwork).

This in-person meeting solidified collaborations, sparked new ideas, and underscored the importance of teamwork in driving innovation, reaffirming the consortium’s commitment to transforming the construction sector and building a greener future. Partners left Stuttgart energised, with a clear blueprint for the next phases of the project.

Stay tuned for more updates and developments – subscribe to our newsletter to follow SNUG’s journey!