Circular Construction for Resilient Cities: The Role of Recycled Materials in Urban Adaptation to Climate Change

Climate change is no longer a future threat, it is a present reality that affects our cities, our infrastructure, and our daily quality of life. Extreme events such as heat waves, torrential rains, and prolonged droughts are increasingly common, putting the adaptive capacity of urban environments to the test across all regions.

In this context, urban resilience, the ability of a city to withstand, adapt to, and recover from these challenges, has become a priority for governments, businesses, and citizens alike.

To adapt effectively, we must ask ourselves: how do we build more resilient cities? How can we adapt our construction models to meet new demands and challenges? One key lies in transforming the construction sector toward a more sustainable, circular, and innovative model. And this is where recycled materials play a fundamental role.

The construction sector accounts for approximately 40% of global energy consumption and generates more than 30% of solid waste in Europe. Unsustainable practices also make it responsible for a significant share of greenhouse gas emissions, both from material production and construction processes.

Urban growth demands new infrastructure, housing, and public spaces, which in turn increases the consumption of natural resources such as sand, gravel, cement, and water. This is why the transition to a circular economy is so crucial, shifting from a “take, make, use, dispose” model to one that reuses resources, turns waste into raw materials, and creates high added value products with lower environmental impact.

One of the sector’s major challenges is the management of construction and demolition waste (CDW), which makes up a significant portion of total urban waste. In particular, recycled aggregates, derived from CDW, are proving to be an effective and sustainable alternative to natural aggregates. Their use is expanding in:

- Mortars, where they can partially replace natural sand while maintaining mechanical properties suitable for non-structural applications.

- Concrete, especially in prefabricated elements, pavements, or secondary structures, with promising results in durability and strength.

- Cement, through the incorporation of additives such as fly ash or blast furnace slag, which reduce the need for clinker and therefore CO₂ emissions.

These innovations help reduce the extraction of natural resources, lower the carbon footprint of materials, and promote circularity in the sector. At BECSA, we are actively exploring these solutions, integrating them into real projects and collaborating with technology centers to validate their performance.

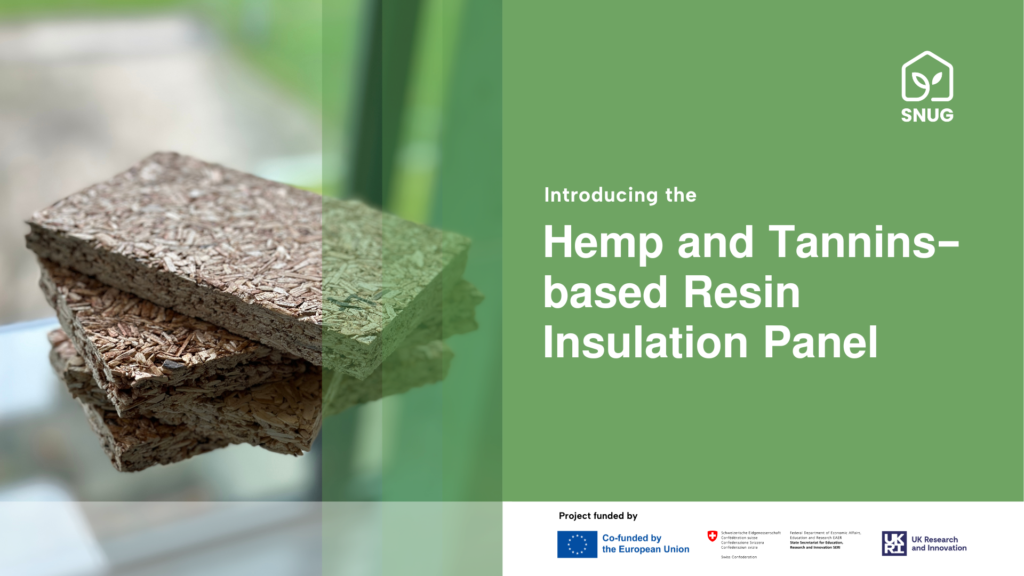

Likewise, energy efficiency in buildings is another key pillar of urban resilience. A well-insulated building not only consumes less energy, but also offers greater thermal comfort, reduces emissions, and improves occupants’ quality of life.

Insulating materials – such as mineral wool panels, polyurethane foams, reflective materials, or even bio-based solutions – are evolving rapidly. Their integration into facades, roofs, and enclosures helps reduce energy demand for heating and cooling, while also enhancing thermal and acoustic performance, contributing to energy certification and building sustainability.

Moreover, the use of recycled or recyclable insulation reinforces the circular approach, closing the material life cycle and minimizing environmental impact. Within the SNUG framework, these solutions align with the vision of creating more efficient and adaptable urban environments.

Complementing these physical solutions, digital transformation is gaining momentum in the construction sector. Within this shift, artificial intelligence (AI) is emerging as a key tool to enhance decision-making throughout the construction lifecycle.

AI is enabling the design optimisation, using algorithms that analyse multiple variables to propose more efficient and sustainable solutions. At the same time, predictive project management, with models that anticipate delays, cost overruns, or quality issues, allows for proactive planning, such as the automated quality control, using computer vision and sensors to verify execution in real time. In addition, energy modeling, through simulations that assess the thermal behavior of buildings before construction begins.

At BECSA, construction company of Simetría Grupo, we are actively exploring these technologies, both in internal projects and in collaboration with start-ups and research centers. AI does not replace human expertise, but it serves as a powerful complement, offering new capabilities to build better, faster, and with less impact. Adapting our cities to climate change requires a profound transformation of the construction sector. The use of recycled materials, improved energy efficiency, and the integration of artificial intelligence are three fundamental pillars for advancing toward sustainable, resilient, and innovative urban models.

However, this transition toward resilient cities is not the task of a few – it requires collaboration across the board. From public administrations, which must promote regulations and policies that support circularity, to universities and research centers, which can generate knowledge and validate new solutions. And of course, the companies that make up the construction ecosystem, such as BECSA, committed to developing more sustainable and efficient solutions.

Circular construction is an opportunity to rethink how we inhabit our cities, how we design them, and how we adapt them to the challenges of the 21st century. At BECSA and Simetría Grupo, we believe this transformation is not only possible, but also essential. And we are committed to leading it through innovation, sustainability, and collaboration.

Download full article in pdf here.