Turning Insulation Waste Into Material Value: A Circular Aerogel Approach

The Lifecycle Gap in High-Performance Insulation

Insulation materials are usually assessed when it is chosen and installed. At that point, designers check performance values and compliance, and the job is considered done. What happens afterwards – during processing, replacement, or end-of-life – is often outside the practical focus of design and procurement decisions. For high-performance insulation materials, this gap is particularly relevant.

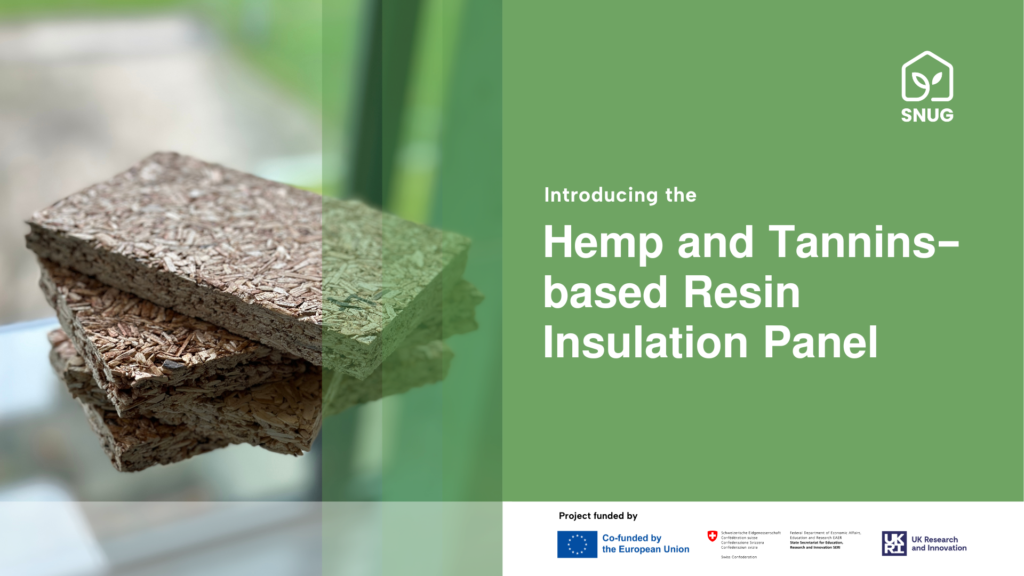

Aerogel-based insulation is used where conventional solutions are insufficient. Thin build-ups, complex geometries, retrofit constraints, and demanding fire or moisture requirements define its typical applications. In these cases, material efficiency per unit thickness is the primary driver. However, this same high level of optimization also influences how the material behaves during cutting, handling, and potential recycling.

Technical Requirements for Aerogel Waste Reprocessing

In practice, insulation waste is generated long before end-of-life. Offcuts, trimming losses, rejected components, and process residues are part of normal production and installation workflows. Treating these streams as generic waste ignores their material value and their specific behavior. For advanced insulation materials, reuse or recycling cannot rely on generic assumptions. It requires a clear understanding of particle size, bonding mechanisms, dust formation, and stability during reprocessing.

Applied experience shows that transforming insulation waste into a usable secondary material is possible, but only under controlled conditions. The process must be compatible with existing production steps, avoid additional binders where possible, and maintain predictable thermal and mechanical behavior. Small changes in processing – such as flake size or pressing conditions – can significantly affect the final material performance. These factors are measurable and must be managed accordingly.

Bridging the Gap Between Concept and Building Scale

Testing such approaches at building scale reveals constraints that are not visible at concept level. Installation conditions, health and safety requirements, and interaction with other building components set practical limits. In occupied buildings, these constraints are non-negotiable. Circular solutions that introduce excessive dust, instability, or uncertainty cannot be justified, regardless of their theoretical potential.

Collaborative research environments such as SNUG provide a framework to examine these issues under real conditions. Demonstration activities make it possible to compare intended material pathways with actual outcomes. They also allow early identification of approaches that require redesign or relocation within the system, rather than forced implementation.

In this context, AGITEC’s contribution within the SNUG project focuses on testing how production and processing residues from aerogel-based insulation can be handled, reprocessed, and reintegrated under realistic conditions. This work does not aim to present a finished solution, but to evaluate material behavior, processing constraints, and practical limits when circular concepts are applied in real construction environments.

Engineering a Verifiable Circular Economy

This leads to a more precise understanding of circularity. Material value is not preserved by definition; it is preserved through process control, testing, and adaptation. A circular insulation concept is only valid if the recycled or reused material performs reliably, can be handled safely, and integrates into standard construction workflows without additional risk.

From this perspective, sustainability becomes an engineering task rather than a declaration. Thermal performance, material processing, and waste handling must be evaluated together. When insulation waste is treated as a technical resource rather than a residual problem, it becomes possible to close material loops in a controlled and verifiable way.

Turning insulation waste into material value is therefore not a question of intent, but of execution. For high-performance aerogel insulation, progress toward circularity depends on measurable behavior, realistic constraints, and continuous refinement based on evidence from practice.

Download full article in pdf here.