Solution 2

Sustainable self-leveling mortars with PCMs

Partners

involved

What are sustainable self-leveling mortars

Self-leveling mortars (SLMs), also known as self-leveling cement or compounds, are specialized cement-based mixtures formulated to create an extremely flat and smooth surface with minimal manual effort. They are highly fluid due to specialized chemical additives and are designed to spread and level themselves across a subfloor under their own weight, effectively filling in low spots and imperfections. Their primary application is as an underlayment to perfectly prepare uneven concrete, plywood, or tiled floors before the installation of final floor coverings like ceramic tiles, vinyl, or wood flooring, ensuring a smooth finish and often allowing for quick foot traffic due to their rapid-setting time.

The solution involves developing a self-leveling mortar (SLM) that incorporates Phase Change Materials (PCMs) to enhance thermal energy storage in floors. This technology is designed to work in conjunction with radiant heating systems to shift energy consumption.

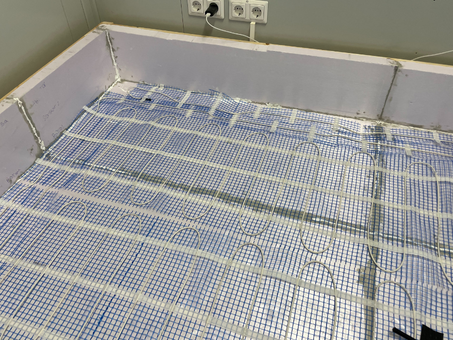

- Initial Formulation: A self-leveling mortar was developed and installed in a demonstration site (Norway) incorporating 5% graphite-based PCMs (a blend of A20, melting at 20∘C, and A34, melting at 34∘C).

- Application: The mortar was successfully installed as a floor covering in the bathroom of the demo apartment in Norway.

- Composite Panels: The project also works on multilayer panels combining these bio-based mortars with bio-based panels or wood. The design emphasizes minimized thermal bridges and optimized installation for easy replacement and recycling.

The primary goals are to achieve both improved performance and increased sustainability:

- Energy Efficiency:

– Develop an SLM with PCMs to provide significant energy saving (latent heat storage) and also to reduce the building’s overall energy consumption.

– Enable the shift of energy use to off-peak hours when combined with radiant heat floors, which is expected to reduce electricity costs by around 18% and CO2 emissions by up to 7%.

- Workability and Safety: Ensure the mortar with PCMs maintains similar or better workability than commercial SLMs while meeting all relevant technical and safety indicators (e.g., TEK17 Regulations).

- Sustainability & Circularity:

– Reduce Embodied Energy and CO2 Emissions by replacing conventional components (like commercial mortar and oil-based PCMs) with sustainable alternatives (blended OPC/Geopolymer and bio-based PCMs like coconut oil).

– Utilize a Biochar-PCM composite (where biochar is impregnated with the PCM) to replace part of the sand, allowing for a higher percentage of PCM and increased energy storage capacity.

The project has achieved several concrete milestones:

- Successful Installation: The initial self-leveling mortar with PCMs was developed, tested at the mock-up level, and successfully installed in the demo building in Norway.

- Workability Confirmation: The workability of the PCM-enhanced mortar was confirmed to be similar to or better than the commercial reference mortar, both through experimental measurements and feedback from installation workers.

- Compliance: The mortar meets all necessary technical and safety indicators (e.g., TEK17 Regulations) for use as a floor covering.

- Bio-Based Formulations (In Progress): Several mortar formulations have been successfully tested at the lab scale as potential bio-based skin for the composite panels.

The next period will focus on improving sustainability, final material characterization, and reporting energy results:

- Sustainability Improvement:

– The first-generation mortar will be improved by replacing the commercial mortar base with a sustainable blend (OPC or Geopolymer) formulation.

– The expensive, oil-based PCMs will be replaced by bio-based PCMs (like coconut oil) incorporated into a biochar matrix to create the new GEO-Biochar-PCM mortar.

- Energy and Cost Reporting: Results from the mock-ups and Norway demo monitoring of energy consumption will be analyzed to determine the actual energy savings and calculate the material’s payback time and real cost.

- Addressing Panel Attachment: Further research is needed to improve the bond between the mortar and the biopanel/wood in the composite sandwich panels, as the current lab-scale mechanical fixation method was unsuccessful. Several new systems will be studied to enhance bonding and minimize thermal bridges.

- Industrialization Challenge: The project will continue to face the challenge of finding cost-effective and reliably supplied PCMs for industrial-scale production.